O Minimize the length of the vent pipe. Per ASME B313-2016 Sections 32263.

Avoid Pressure Relief System Pitfalls Aiche

The correction factor K N can be calculated the following way.

. MOTEMS Marine Oil Terminal Engineering and Maintenance Standards MOTEMS Standards Completed Will Define Specific Engineering Criteria for Both Existing and New MOTs Will Allow the SLC to Accomplish Their Goal of Protecting the Environment and Ensuring Safe Operations Through the Enforcement of the. The discharge pipe shall be a minimum of 1-12 inches in diameter and have a union or other approved quick disconnect assembly to make the pump accessible for servicing. These designs provide stable non-chattering valve performance and high capacity at 10 overpressure.

Both at rated conditions as a standard practice Mach velocity shall not be higher than 07. Design pressure can be considered in place of MAWP for this purpose as design pressure does not exceed MAWP. Piping that can be overpressured due to process control failure eg high-pressure steam letdown control into a low-pressure.

Piping and valve support becomes more critical on larger pressure safety valves and pressure safety valves that have high set pressures discharging to atmosphere. A psv at our plant is installed on hydrocarbon service natural gas having set point of 125 psig and is conventional typein existing case this psv discharge pipe height is 6 ft. This riser shall be at least 30 meters away from any furnace regardless of the height of riser.

The method of analysis provides a simple technique for determining pressure within a discharge piping system. Code allows the designer to use the adjusted reduced capacity of the relief valve to size the relief vent. Require relief devices on the discharge side for deadhead protection.

The pressure drop should be based on rated capacity of the PSV not the required capacity as pipe will handle a flow corresponding to rated capacity of the PSV when it releases the fluid. Section 110152 2013 California Plumbing Code. Also note that it is important not to exceed PSV maximum backpressure.

Of 65C for sewer see local Municipal By-Laws Steam A safe point outside the building see below. 87K - 150K Glassdoor est 9d. K N 1 if P 1 10339 kPa abs.

Set pressures lower than 120 of the design pressure may be. Ability to report on trends. Entrance losses at the nozzle of the vessel Pipe and fitting losses in the piping to the three-way valve Losses in the three-way valve.

The reaction forces that can develop from the valves relieving to atmosphere can be significant. Pressure safety valve required discharge area in the case of steam. Nominal pipe size.

Piping Design Team Lead. The method is based on adiabatic flow and uses local Mach number to relate expansion of the gas in the pipes to a mass flow function. The line is a PSV discharge to atmosphere.

When system pressure reaches the desired opening pressure the. Segments of liquid-filled piping that have a high risk of overpressure due to thermal expansion eg unloading lines should have relief devices. There are three components of inlet losses to the relief valve.

Figure F2-2 is a simple sketch showing the disc held in the closed position by the spring. Outlet lines discharging to flare headers are sized to limit the Mach number to 07. Normally PSV discharge piping would have lower design pressure since its open pipe to flare ie pressure is limited to backpressure from hydraulic losses in the piping and flare system only.

PSV discharge line shall take in to account both the blocked scenario and the fire scenario. Terminate the discharge pipe not more than 6 inches from the floor in a manner to prevent splashing and scalding of personnel or damage to sewers eg. Proper valve and discharge piping support design is essential.

Vent piping o The diameter of the vent pipe must be equal to or greater than the safety valve outlet. Vi While set pressure cannot exceed the maximum allowable working pressure MAWP for single operating PSV it can exceed the MAWP for one or more PSVs in case of multiple operating PSVs eg. Cool to a max.

PRV discharging Hydrocarbon vapors to atmosphere should be provided with outlet piping at least 3 meters above any equipment within a horizontal distance of 15 meter or 45 meter above the roof of the nearest building whichever is higher. O The vent line should be sized such that back pressure is not placed on the drip pan elbow. Type of reducers used in PSV discharge Conc.

You can use either a Concentric or Eccentric Reducer in the discharge of a PSV if and only if you are going from the smaller PSV discharge nozzle size to a larger discharge line size to reduce the back pressure. The sonic conditions at the outlet will lead to a significant amount of backpressure. There are 2 PSVs.

K N 002764P 1 -1000 003324P 1 -1061 if 10339 P 1 22057 kPa. Typical Open Discharge PSV Connection PSV Reaction force at the point of discharge for Gas Services in lbf F W366 KT K1MAP Here Wflow of any gas or vapor in lbmhr Kratio of specific heats CpCv at the outlet condition Ttemperature at the outlet in Degree R Mmolecular weight of the process fluid. See Figure 1 and 30224 f see Figure 2 a thermal relief valve may be set up to 120 of the design pressure of the protected system with the owners approval as long as the allowable accumulation criteria in 30224.

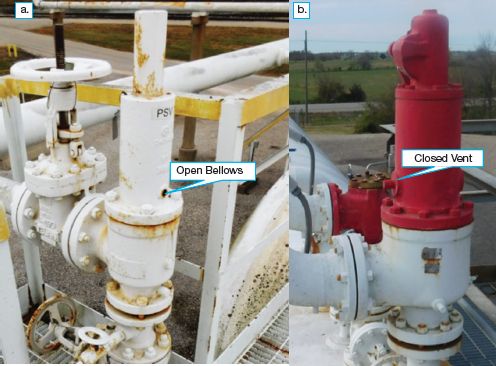

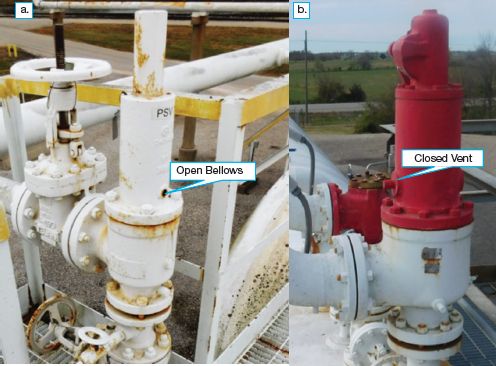

For PSVs discharging directly to the atmosphere limiting the Mach number to 07 is not practical and a sonic condition could be allowed in the discharge piping. O The discharge outlet of. Beyond these design and instrument based protection measures the philosophy of containment and abatement steps such as pressure relieving devices flares physical dikes and Emergency Response Services is employed A pressure safety valve PSV is a safety device used to protect equipment from over pressure conditions.

Reducer in PSV discharge FSU or FSD. 20 May 15 1818 Our client is insisting that PSV discharge piping must have the same design pressure as the PSV set pressure of 1200 kPag 175 psig. This is to avoid noise and too much force in the line while the PSV opens.

I have done its dispersion analysis on dnv phast 70 software to check the scenario in case of psv popping than up to what extent the flammable area will be present. Hi Guys I am checking a piping isometric from our detailed designer. PSV inlet pipe should be sized so as to limit non-recoverable pressure drop in the pipe to less than 3 of set pressure of the PSV in line with API 520 part II.

Design Static head Submerged Discharge Maximum static head Free Discharge Max WS. Directs others personnel in routine engineeringdesign work as they are assigned by the design supervisor or Project Manager. This paper addresses manifolded discharge piping system design.

Mitigating Relief Valve Chatter Through Side Branches

Your Opinion On This Sticky Subject Psv Closed System Intergraph Cadworx Analysis

The Dos And Don Ts Of Isolating Pressure Relief Valves Valve Magazine

Atmospheric Termination Of Relief Valve Discharge Piping

Modeling Relief Valve Pressure Safety Valve Thrust Force Blog

Piping Engineering How To Design Safety Valve Line Youtube

Water Worker Amtrol Steel Water Heater Expansion Tank 15 H X 11 5 W Water Heater Water Heater Expansion Tank Water Heater Expansion Tanks

Relief Valves For Centrifugal Pumps According To Nfpa 20 Fire Protection Specialists

0 comments

Post a Comment